Defect classification

The quality analysis of seed batches is essential: it is what will define the selling value of your product. In addition, the obvious intention is always to market a product with the best possible quality. However, guaranteeing this standard manually in hundreds of batches per day is a process that requires a large number of people involved, leading to deficits in precision and consistency, fruits of human subjectivity.

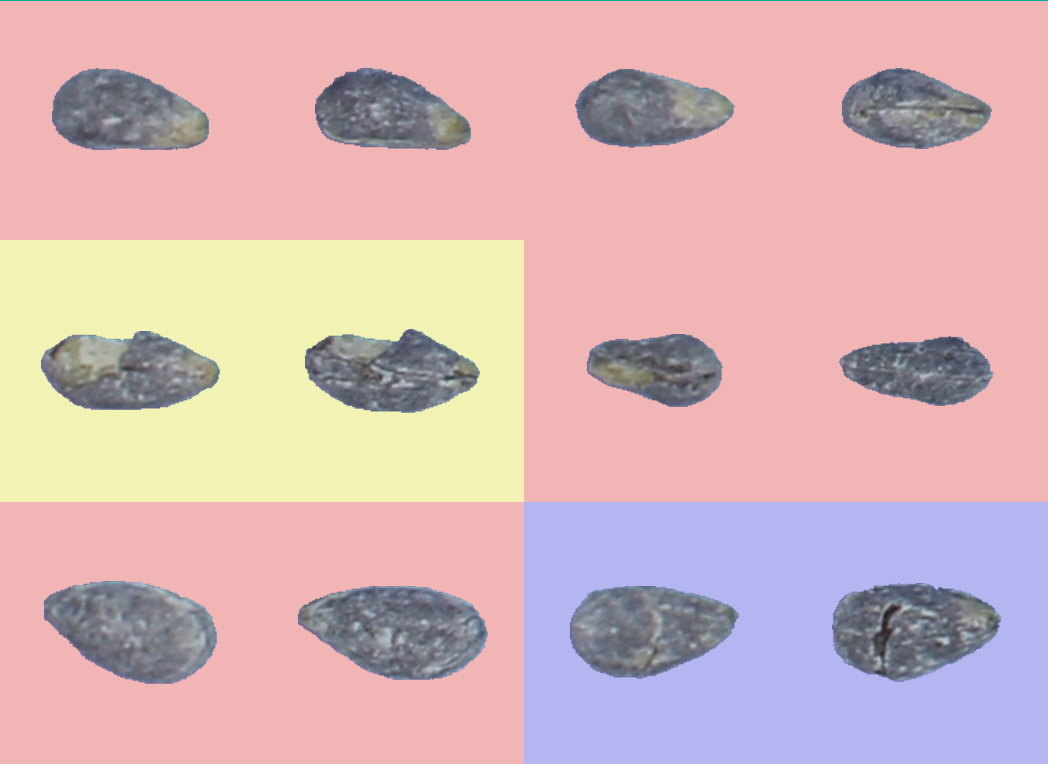

GroundEye uses several AI tools to solve these issues. For each sample recorded, hundreds of color, geometry, and texture characteristics are measured for each seed present, and this data is used to train automated classifiers. In summary, intelligences for each of the defects of interest are able to verify their presence or absence in each of the seeds. Thus, statistical and individual results are easily obtained by the system in a few clicks.

In the system, it is still possible to track which seeds of each of the defects are being analyzed. In other words, when opening an analysis of soybean seeds whose result says it has 10% of seeds with mechanical damage, it is possible to visualize which ones they are and to check the results.

The formatting of the results can be configured according to the user’s needs, being able to come out individually (per seed), statistically (percentage of defects per sample) or even use the data for automated decision-making. In other words, GroundEye can use the result of the AIs to approve or reject a sample according to your company’s standards.

Seed analysis using GroundEye is present throughout Brazil – as well as in Argentina and Thailand – operating with various crops such as soybeans, corn, cotton, chia, chickpeas, beans, sorghum, wheat, and forest. The possibilities are endless! Contact the Tbit commercial team to better understand how GroundEye can optimize your company’s processes.

INTERESTED?

Get in touch to find out more!